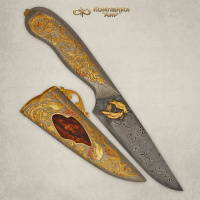

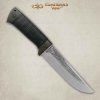

( The steel 50x14MF also used for machetes AiR Zlatoust )

Brand history :

The production was organized in Moscow, later moved to Kazan, where it is now based. The main field of activity is metal processing and manufacturing of metal products. These are not only knives, it all started with medical equipment, turbine blades for aircraft engines, and various other products. To create a technology for the production of knives was proposed by meat processors, and later orders for hunting knives, then tourist knives began to come. The production of combat knives at the Melita-K plant was started by the Katran knife

Steel 50X14MF for Melita-K knives :

Steel 50x14mf or the so-called "50-ka" is used for the manufacture of scalpels for medicine, kitchen accessories, throwing and long blades such as machetes.

Initially, the scope of application of 50X14mf was limited to the manufacture of exclusively medical tools and kitchen knives. This is due to the resistance of the alloyed alloy to corrosion damage under the influence of water and chemically active substances. It is important that it does not cause allergies. The presence of chromium and carbon in the composition of steel is sufficient to suppress corrosion processes, as well as the formation of iron carbides during quenching - the hardness of the material reaches 57-58 Rockwell units, which means both high hardness and the necessary elasticity for optimal consumer properties.

Advantages :

- relatively affordable cost;

- sharpening lasts a long time;

- you can sharpen and even re-sharpen or edit the blade at home without any problems;

- the combination of hardness and elasticity allows the steel to transfer shock and fracture loads, which makes it possible to use this "50-ku" material for long knives of the "machete" format.

Minuses :

- Despite the presence of corrosion inhibitors in the composition of a knife made of steel 50x14mf, it is necessary to keep dry and clean - in principle, this requirement is relevant for blades made of any alloy. Otherwise, a dirty blade in a sheath will rust with prolonged contact with moisture.

Chemical composition :

- carbon (0.48-0.55%) - strengthens steel due to the formation of iron carbides, increases the hardness and endurance limit;

- chromium (14.0-15.0%) is a corrosion inhibitor, provides hardening during maintenance, improves resistance to abrasive wear;

- manganese (within 0.6%) - necessary for the deoxidation of steel, purification of the alloy from sulfur and oxygen;

- molybdenum (0.45-0.80%) - the material receives heat resistance and creep resistance when the temperature rises. And also this element provides high hardness of the hardened material, especially since the presence of vanadium (0.10-0.15%) excludes the formation of temper brittleness, and grain refinement helps to improve the mechanical characteristics;

- silicon (within 0.6%) provides good strength characteristics (elasticity and yield strength increases without changing plasticity), wear resistance and hardness also improve after maintenance.

Corrosive properties :

To increase the corrosion resistance, it is enough to carry out maintenance - after exposure to high temperatures, the resistance to the effects of chemically active media, in particular, chlorine-containing ones, also increases. So medical instruments from this brand can easily tolerate pre-sterilization cleaning, sterilization and disinfection. It is also worth noting the resistance of "50" to the effects of a number of acids and weak alkalis, the reaction to organic organisms is also neutral.

Application :

Based on all of the above properties, the main purpose of steel 50x14mf is the manufacture of cutting tools and knives.

In medicine, scalpels are produced from this brand due to the inertness of steel to an organic environment. Surgical instruments made of 50x14mf are distinguished by an increased service life. Such scalpels become unusable only after 4 surgerys, while scalpels from another popular brand 100X13M in just 2 surgerys.

In the household, food knives are made of steel 50x14mf. They have the following advantages:

- Long shelf life of sharpening. With proper use of the tool, the steel remains sharp for up to 2 months.

- Technologically uncomplicated sharpening process. It is possible to sharpen 50x14mf in ordinary home conditions and this does not require much experience in this matter.

- The blade is resistant to impact loads, which allows the use of this steel in the manufacture of large blades.

- Despite all of the above advantages, 50x14mf has a relatively low cost.

Among the minuses, it is worth noting the formation of pitting corrosion on the surface of the knife with a long period of exposure to moisture.